Thermal Spray Coating Process

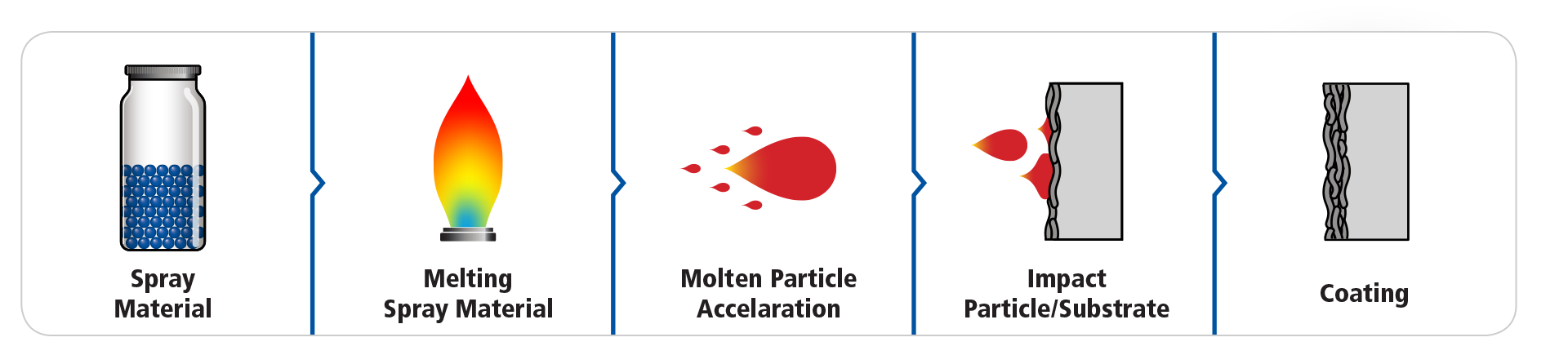

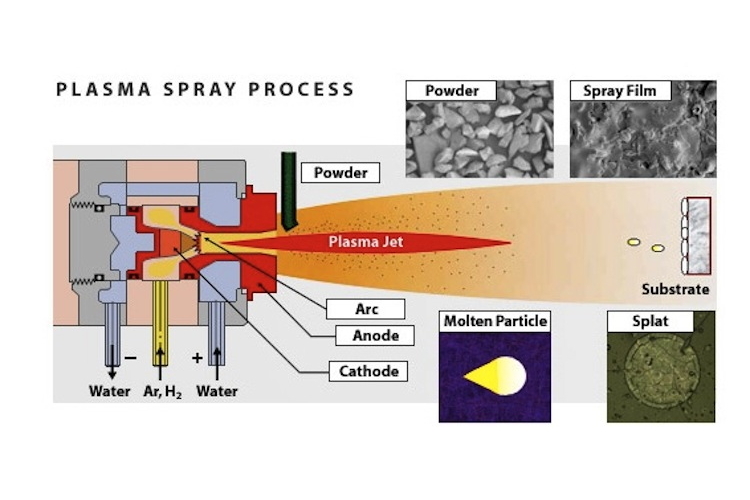

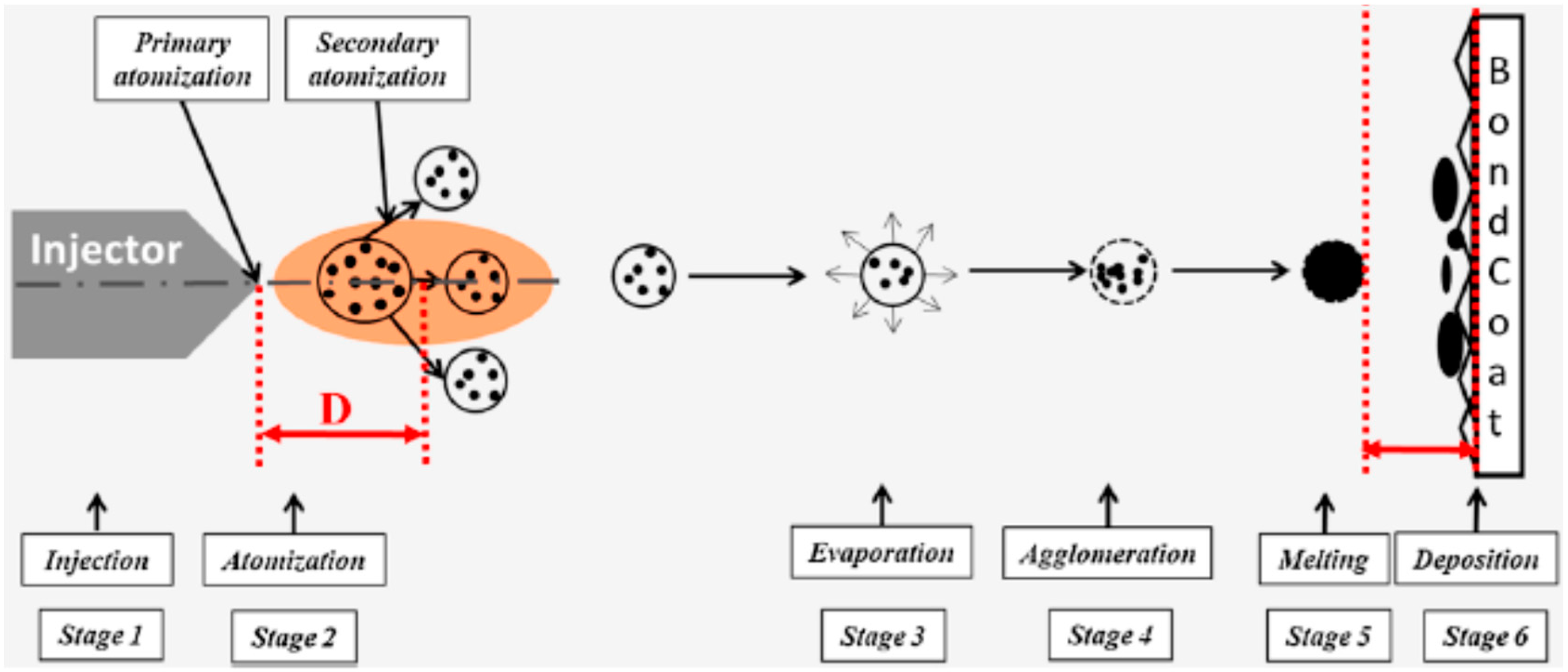

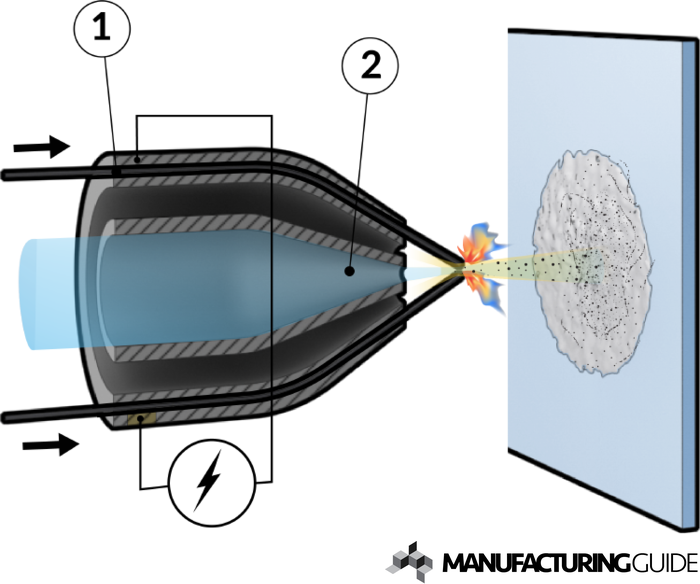

Thermal spray coating process. Material in the form of powder is injected into a very high temperature plasma flame where it is rapidly heated and accelerated to a high velocity. The material is then melted into droplets and sprayed onto a surface at a high velocity. The Plasma Spray Process is basically the spraying of molten or heat softened material onto a surface to provide a coating.

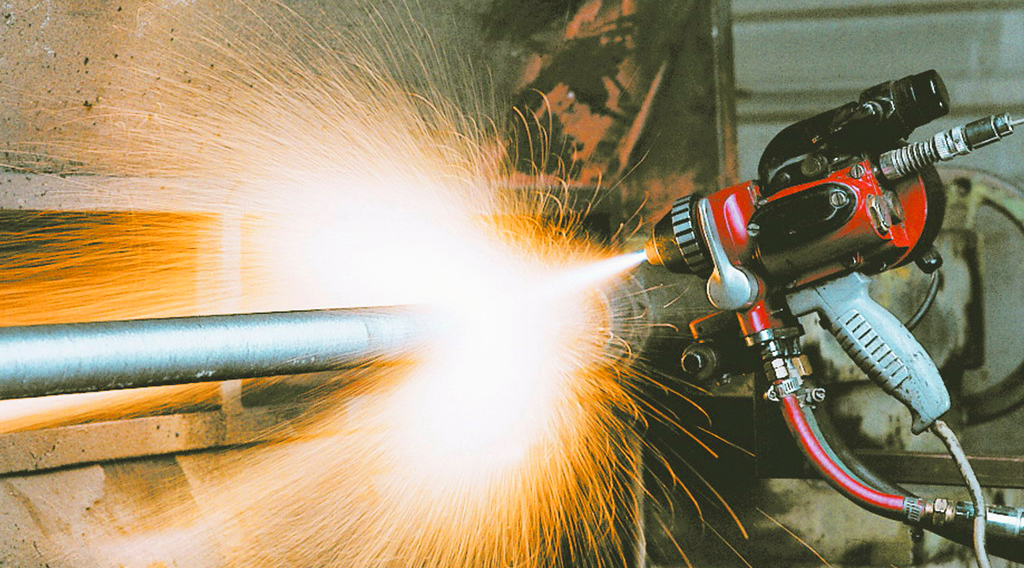

How Does Thermal Spray Work. CUI corrosion under insulation plagues pipeline systems in todays petrochemical industry. Thermal spray is an industrial coating process that heats or melts metallic or ceramic materials and deposits them onto a surface.

It can also correct multiple industrial problems. Thermal Sprayed Aluminum Helps Reduce Corrosion Under Insulation Issues. Splat shapes in a thermal spray coating process.

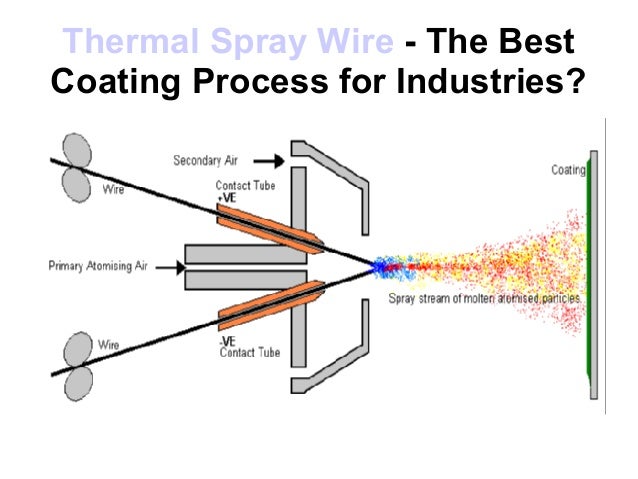

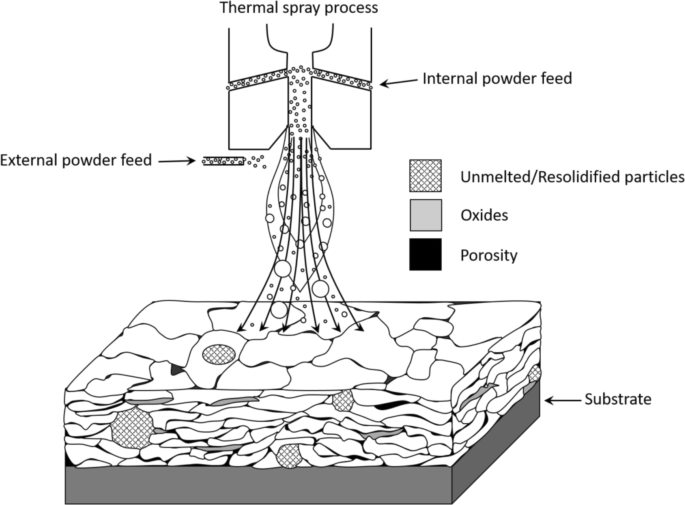

Thermal spraying is an industrial coating process that consists of a heat source flame or other and a coating material in a powder or wire form which is literally melted into tiny droplets and sprayed onto surfaces at high velocity. Porosity may be beneficial in tribological applications through retention of lubricating oil films. Thermal spray processes represent an important and rapidly growing group of surface modification technologies using a very wide range of solid feedstock materials including metals and alloys hardmetals ceramics and polymers mostly in the form of particles wires and suspensions.

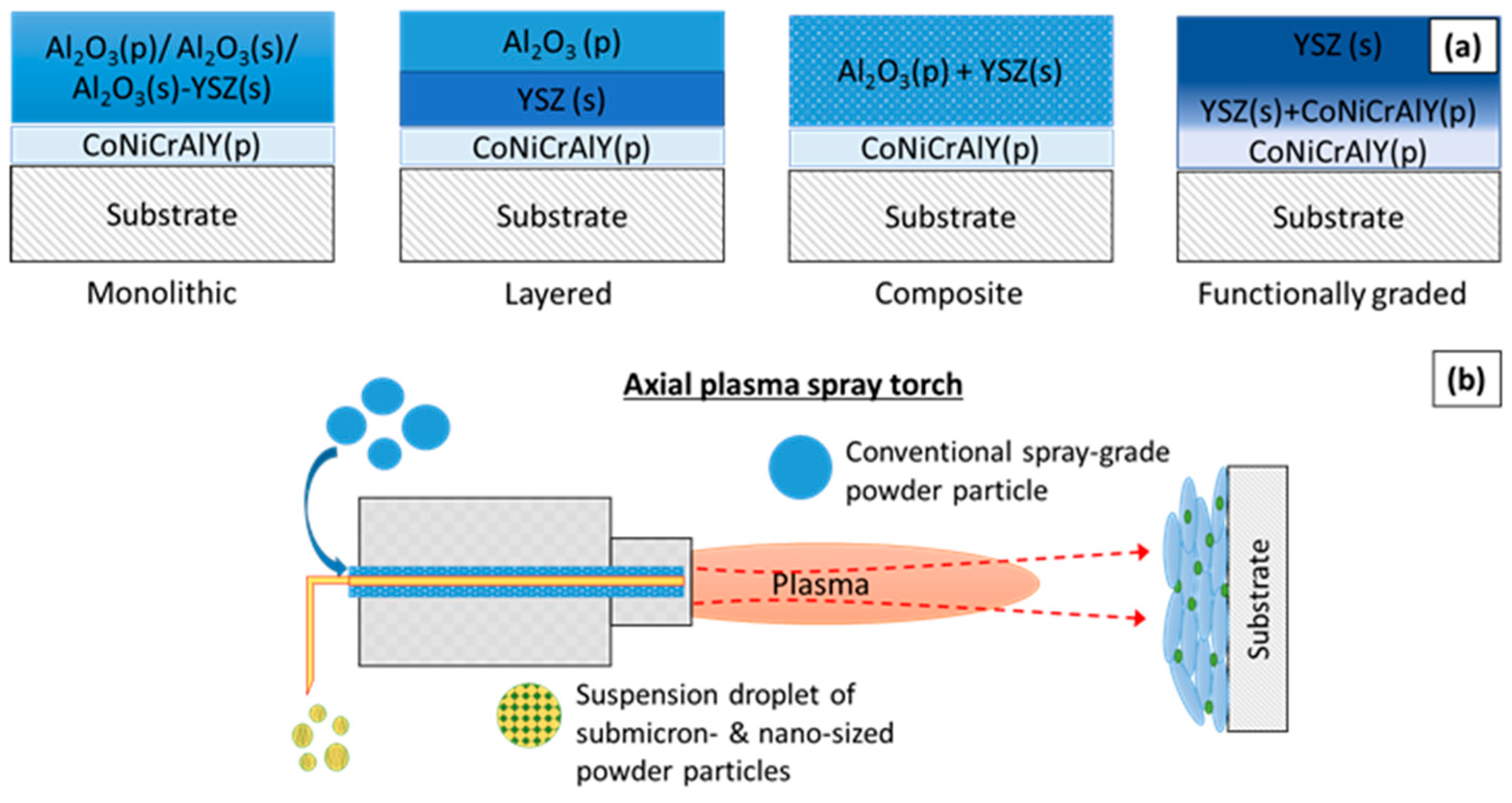

Principle A and actual set up of the thermal spray coating set up B. Mal spray process as a whole is very complex because the process involves many variables that concurrently influ- ence the properties of the deposited coatings 60. Porosity also is beneficial in coatings on biomedical implants.

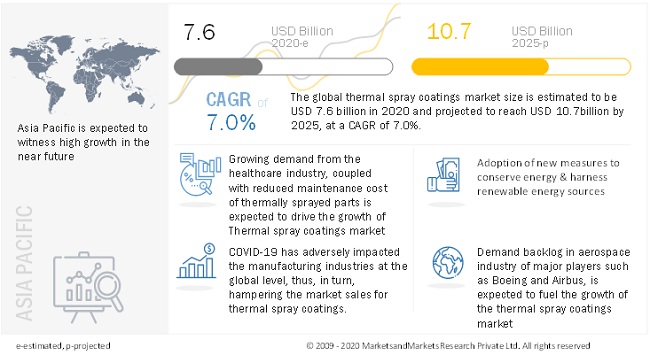

Base on the heat source the thermal spray coating process can be classified as shown in following flow chart fig. It is a versatile process that can use a large range of materials starting from pure metals to alloys carbides ceramics and even composites. Thermal spray coatings may contain varying levels of porosity depending on the spray process particle speed and size distribu-tion and spray distance.

A large percentage of maintenance budgets is consumed due. Thermal spray is a generic term for processes which are designed to rebuild worn material.

Mostaghimi 1 Journal of Thermal Spray Technology volume 11 pages 2062172002Cite this article.

Other terms used interchangeably with thermal spray are metal spray flame spray plasma spray HVOF spray plasma coating and. A large percentage of maintenance budgets is consumed due. Thermal Sprayed Aluminum Helps Reduce Corrosion Under Insulation Issues. 26 November 2020 By AA Coatings. Principle A and actual set up of the thermal spray coating set up B. Thermal Spray Coating A group of coating processes where the coating is deposited on a prepared substrate by applying a stream of particles metallic or nonmetallic which flatten more or less forming platelets called splats with several layers of these splats forming the coating Any material on almost any substrate 10162014 3 Dept. It is economically viable and has wide scope of. Mal spray process as a whole is very complex because the process involves many variables that concurrently influ- ence the properties of the deposited coatings 60. Thermal spraying is an industrial coating process that consists of a heat source flame or other and a coating material in a powder or wire form which is literally melted into tiny droplets and sprayed onto surfaces at high velocity.

Porosity also is beneficial in coatings on biomedical implants. CUI corrosion under insulation plagues pipeline systems in todays petrochemical industry. Base on the heat source the thermal spray coating process can be classified as shown in following flow chart fig. Mal spray process as a whole is very complex because the process involves many variables that concurrently influ- ence the properties of the deposited coatings 60. 26 November 2020 By AA Coatings. Classification of various thermal spray coating processes A B. It is economically viable and has wide scope of.

Post a Comment for "Thermal Spray Coating Process"